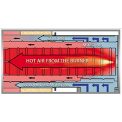

The “modulating” operation under the control of a PLC unit enables the burner to work from minimum to maximum delivery fully automatically until the set temperature is reached. This function also allows the burner to reach and maintain its set point more efficiently saving fuel, time and money, giving our system some great advantages over traditional cheaper modular burners.

Another great advantage of this new system is that it makes it possible for the operator to use the dryer with different products requiring varying and very different drying temperatures, without needing to replace the burner nozzles.

When burners have a “modulating function”, the operator has only to set the drying air temperature on the control panel for the cereal that he wants to dry.