You are here: Home Master Grain Driers

The Master Driers Range

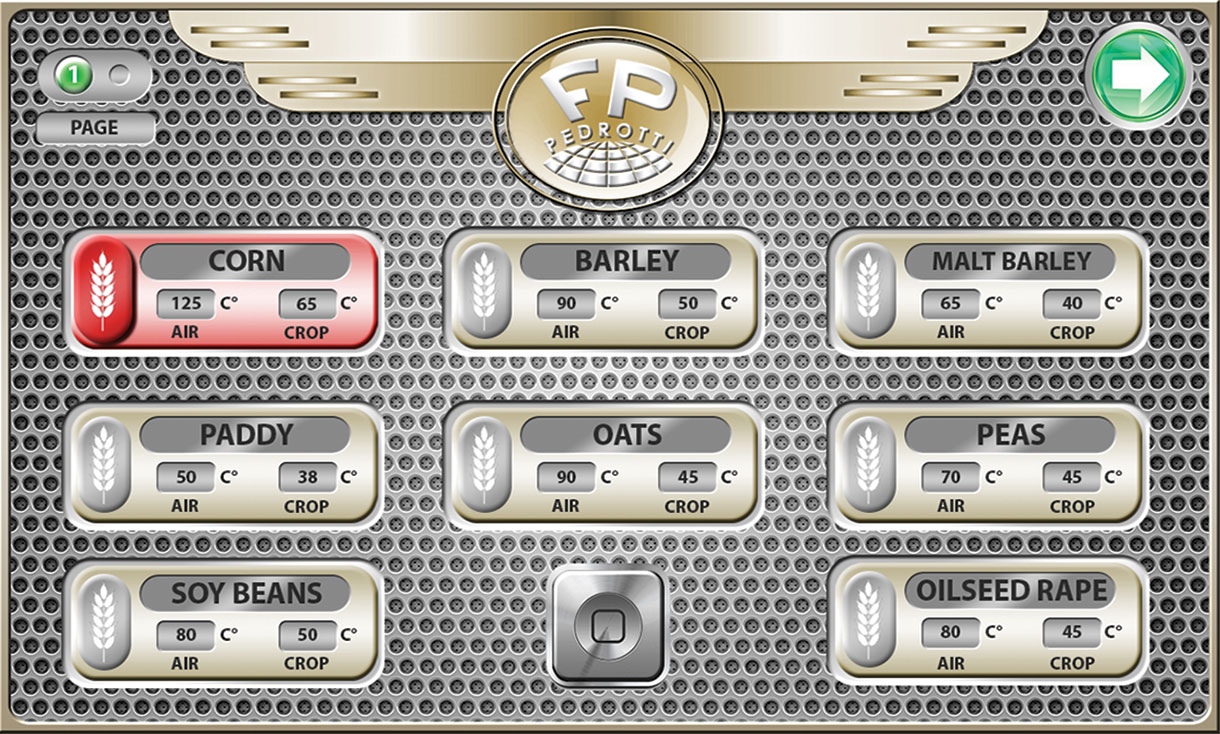

Pedrotti Master Driers are suitable for handling all types of materials and can deal with different climate conditions and cropping systems worldwide. With 15 basic capacities and with specific alternatives to meet individual requirements, the Pedrotti Master Drier is suitable for most applications.

All new machines carry a 3 year factory warranty. The exceptionally high standard of construction of Pedrotti Master Driers makes them durable giving a strong demand for second hand machines. Find out about our Master Care Package.